Chris Luettgen appointed as APPTI Executive Director

Apr 09, 2023 — Atlanta, GA

Portrait of Chris Luettgen

Christopher Luettgen, professor of the practice at the School of Chemical and Biomolecular Engineering and associate director of the Renewable Bioproducts Institute (RBI) has been named as the new Executive Director of the Alliance for Pulp & Paper Technology Innovation (APPTI), effective April 1, 2023.

Luettgen has over 25 years of industry experience, with Scott Paper and Kimberly-Clark Corp., where he most recently served as senior research and engineering manager for the Kimberly-Clark Professional business sector. He has held positions in product development and innovation as well as in capital project management and manufacturing facility leadership.

For several years, Luettgen has served on the RBI Industry Board of Advisors, and he is the current Chairman of the Board of the Technical Association of the Pulp & Paper Industry. He earned his bachelor's degree in Paper Engineering at Western Michigan University (’85), his master’s degree at the Institute of Paper Chemistry, Appleton, WI (’87), and his Ph.D. at the Institute of Paper Science and Technology - now the Renewable Bioproducts Institute at Georgia Tech (’91).

He rejoined Georgia Tech in November 2014 as a Professor of the Practice in the School of Chemical and Biomolecular Engineering, and Associate Director of Pulp and Paper at RBI. He also serves as Director of Industry Strategic Partnerships in the Georgia Tech Professional Education Division.

His areas of interest include: Recycled fiber, renewable cellulosic feedstocks, tissue manufacturing and converting and manufacturing leadership / operations excellence.

Priya Devarajan || RBI Communications Manager

2023 RBI Spring Workshop Experience From a Student's Perspective - Part 2

Aug 30, 2023 — Atlanta, GA

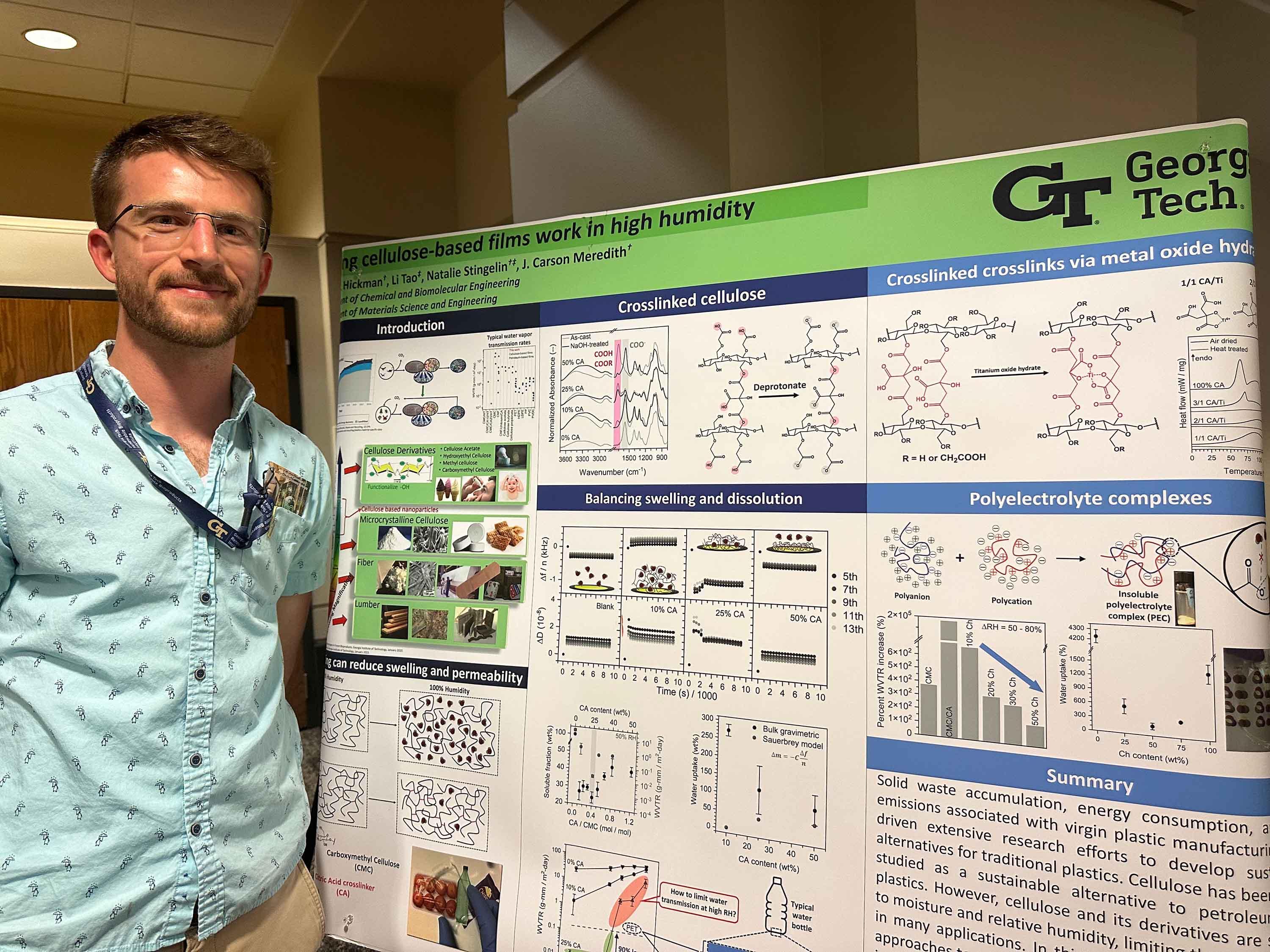

Tanner Hickman at the 2023 RBI Spring Workshop

This is part two of the student experiences series. Tanner Hickman, fourth-year Ph.D. candidate in chemical and biomolecular engineering shares his experience from the 2023 RBI Spring Workshop on "Innovations in Packaging and Circular Economy."

Tell us about yourself.

I am Tanner Hickman and I completed my bachelor’s degree in chemical and biomolecular engineering at the University of South Alabama. Here at Georgia Tech, I am a fourth-year Ph.D. candidate in chemical and biomolecular engineering, advised by Carson Meredith and Natalie Stingelin. My research focuses on exploring different ways to control the properties of natural polymers to make them useful for new applications.

How was your experience at the RBI workshop?

The RBI workshop provided incredibly valuable insights. I gained a comprehensive understanding of the persistent challenges within sustainable packaging, as well as the ongoing research endeavors aimed at tackling them. A key lesson I extracted from the workshop underscores the imperative of a circular economy within the packaging sector. However, it's crucial to note that our focus shouldn't solely revolve around product research; we must also direct attention toward addressing social concerns and broader issues.

What was your main takeaway from the poster session?

One of the best parts of RBI workshops is the opportunities to talk with people from different technical backgrounds, and poster sessions are one of the best ways to get the exchange of ideas flowing. I talked with several people from industry, who all had valuable advice on what it takes to bring benchtop research to application on a larger scale. At the same time, discussions with other researchers in academia are vital for brainstorming new projects, forming collaborations, etc.

What more would you like to see in future events at the Renewable Bioproducts Institute?

I would like to see a workshop that incorporates more interactive elements (in addition to the poster session) to engage participants. For instance, roundtable discussions or panel sessions where experts and attendees can openly exchange ideas and insights could enhance the learning experience.

Priya Devarajan || RBI Communications Program Manager

Splitting Hairs : Identification of Unknown Materials of a Historic Papermaking Tool Through Forensics Fiber Analysis

Sep 10, 2023 — Atlanta, GA

Picture of Dard Hunter and Tekumalla Venkajee during their travels in the Indian subcontinent (left). Daniel Vallejo, Ph.D., prepping the loom fiber sample for Scanning Electron Microscopy (middle), Nasreen Khan, Ph.D., analyzing loom fiber with an optical microscope (right) in Georgia Tech Microscope

Who We Are and the Paper Museum

The Robert C. Williams Museum of Papermaking houses hand papermaking artifacts from around the world. Dard Hunter, a renowned paper historian and founder of the museum, collected many of these objects throughout the early 1900s as he sought to gain more knowledge about this craft. Nearly 100 years later, the museum continues its mission to collect, preserve, increase, and disseminate knowledge about papermaking to the general public. By collaborating with Georgia Tech researchers, and the larger Atlanta community, by using scientific tools, we can unlock hidden information held within the objects, both from a historical and scientific perspective. Recently, two Georgia Tech Postdoctoral Fellows, Nasreen Khan (Paper Museum/RBI) and Daniel Vallejo (School of Chemistry and Biochemistry) sought to uncover more about a loom in the museum’s collection, connected with the history of the Indian subcontinent and Gandhi.

Dard Hunter and Background of the Loom

In the 1930s, Dard Hunter traveled to Asia and the Indian subcontinent (I.e., India, Pakistan, Bangladesh, Kashmir) to document hand papermaking techniques and collect tools and paper samples. At that time many people, including Mahatma Gandhi, aimed to revitalize the Indian hand papermaking tradition by supporting and creating schools to teach the craft [1-3]. Dard Hunter visited several papermaking villages and schools, including those helped founded by Gandhi. Hunter brought a loom back to America that was used to weave a chapri (paper-mold cover or screen), but the information of the specific origins of this loom was lost.

What’s Missing?

While Hunter and other researchers documented and studied hand papermaking tools and materials of this region and time, it was primarily from a historical and cultural perspective [1-5]. Much of their focus has been on the plant materials used to make the paper and molds [1-5]. However, some parts of the handmade molds in Asia were known to also use biological materials sourced from animals, such as silk and animal hair [1-4]. Since the exact origin of the loom and the fibers used to construct the paper mold was not known, the museum was interested in learning more about this object.

With scientific tools, the study aimed to understand more about the fibers commonly used in traditional handmade paper-mold covers in the 1930s Indian subcontinent by using scientific tools. With the availability of high-resolution microscopy technologies and historical documentation at Georgia Tech and the Museum, researchers aimed to either prove or disprove whether the origin of preserved fibers on the loom was from an animal and determine with historical context where the loom was acquired.

What we did and what we discovered

Are the Fibers Really Horsehair?

In forensic analysis, typically the first step to identify unknown fiber or hair samples is to conduct microscopy. Microscopy, or the science of using microscopes to view samples & objects that cannot be seen with the naked eye, is the gold standard for analyzing and identifying unknown fibers by comparison to a library of known reference materials. This is possible because hair from different sources or animals have different “morphologies”, or physical features, that help identify their origin. Thanks to the Materials Innovation and Learning Laboratory (MILL), a hub of scientific equipment for hands-on scientific training of undergraduates at Georgia Tech, the researchers were able to use two different microscope techniques: Light microscopy and Scanning Electron Microscopy (SEM). Thanks to Little Creek Farm Conservancy in Decatur and Kristine Parson, the researchers were able to obtain reference materials for tail and mane horsehair from two horses: Angus and Lightening.

Click the link below to continue reading the story.

Virginia Howell | |Director of the Robert C. Williams Museum of Papermaking

Assistant Professor Akanksha Menon Selected to Receive 2023 ASME Pi Tau Sigma Gold Medal

May 17, 2023 — Atlanta, GA

Portrait of Akanksha Menon

Akanksha Menon, assistant professor in the George W. Woodruff School of Mechanical Engineering, has been selected to receive the 2023 American Society of Mechanical Engineers (ASME) Pi Tau Sigma Gold Medal. The award is presented for demonstrating outstanding achievement in the field of mechanical engineering, within ten years following graduation with a bachelor’s degree.

“I am very grateful to be selected for this award,” said Menon. “As an undergrad just over a decade ago, I served as the President of both the ASME and Pi Tau Sigma student chapters; to now receive this prestigious medal for contributions to the field of mechanical engineering is truly humbling – the journey has come full circle!”

Menon directs the Water–Energy Research Lab (WERL) at Georgia Tech, which focuses on applying thermal science and functional materials to develop sustainable and efficient energy and water technologies. Her research aims to unlock critical fundamental knowledge pertaining to thermally responsive materials with interactions across multiple length and time scales and to engineer them for applications ranging from desalination to thermal energy storage.

The full story is available on the George W. Woodruff School of Mechanical Engineering News Page

Georgia Tech Engineers Develop Carbon Membranes Enabling Efficient Removal and Concentration of Organic Molecules from Water

Jun 05, 2023 — Atlanta, GA

Newly Developed Carbon Membranes Enable Efficient Removal and Concentration of Organic Molecules from Water

The need to remove organic contaminants from surface waters continues to grow due to an increasing influx from industrial, municipal, and agricultural sources. But these contaminants are challenging to remove outside of thermally driven separation processes, such as distilling or drying, which consume significant amounts of energy.

However, researchers in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE) have developed rigid, carbon membranes that effectively remove and concentrate small organic molecules (such as solvents) from water, based on the affinity between the organic species and carbon membrane.

Christopher Jones Wins 2023 Institute Award for Excellence in Industrial Gases Technology

Aug 28, 2023 — Atlanta, GA

Professor Chris Jones

Professor Christopher Jones was selected as the recipient of the 2023 Institute Award for Excellence in Industrial Gases Technology from the American Institute of Chemical Engineers. (AIChE).

Jones, the John F. Brock III School Chair of Georgia Tech's School of Chemical and Biomolecular Engineering (ChBE@GT), will receive the award at the AIChE meeting in Orlando, Florida, this November.

This award recognizes his contributions to ultra-dilute CO2 separations, such as the extraction of CO2 from air, also referred to as “direct air capture” or DAC. The Jones group has played a foundational role in developing materials and processes for CO2 removal from air, and in conjunction with the Lively, Realff, Sholl, and other groups in ChBE@GT, no academic institution has authored more publications on DAC than Georgia Tech.

Professors Jones, Matthew Realff, and Ryan Lively are founding members of the Georgia Tech Direct Air Capture Center, or DirACC.

Assistant Professor Akanksha Menon Awarded $3 Million for Research as part of DOE's Energy Earthshots™ Initiative

Oct 18, 2023 — Atlanta, GA

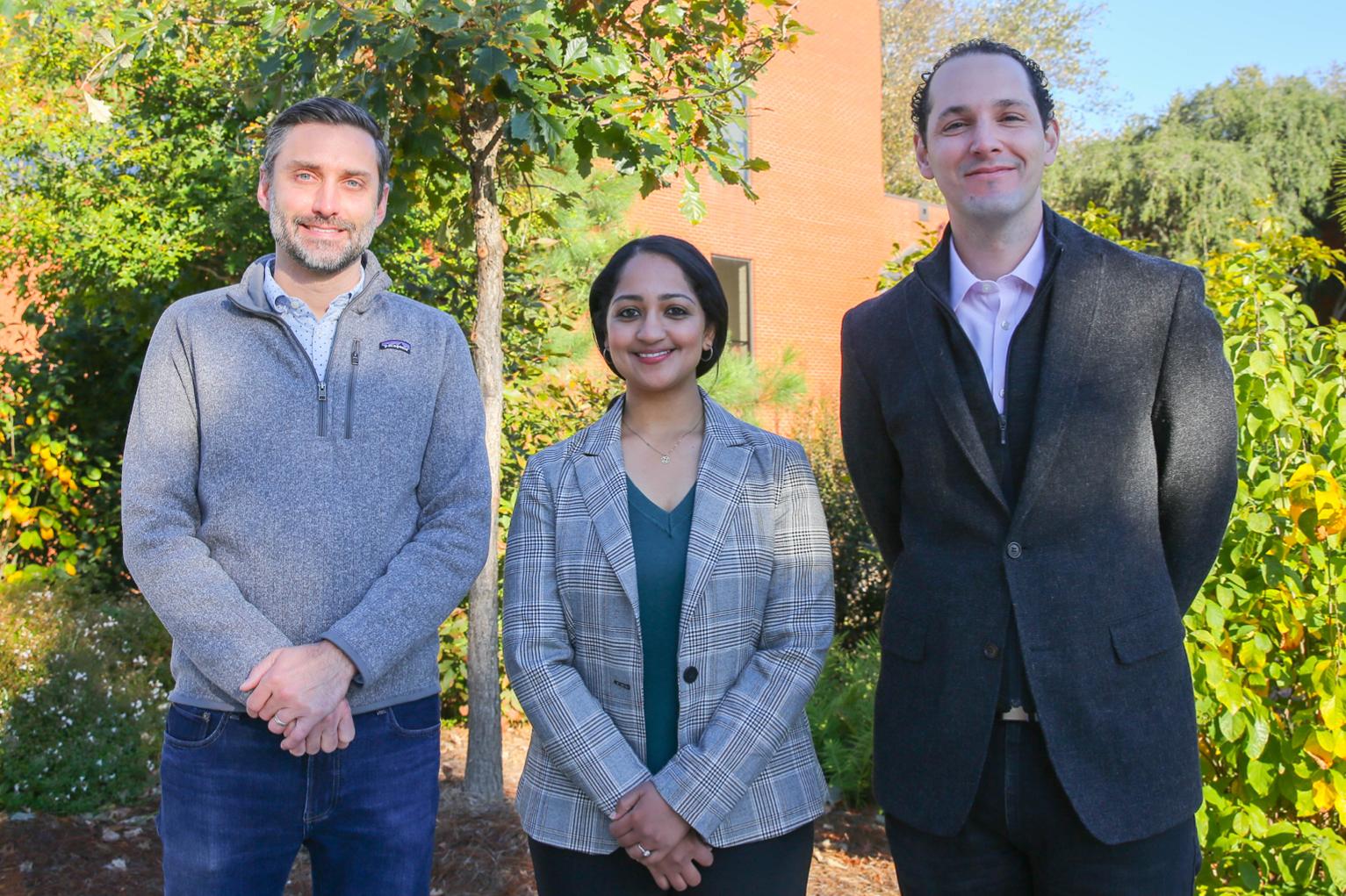

Pictured left to right: Associate Professor Matthew McDowell (ME), Assistant Professor Akanksha Menon (ME), and Assistant Professor Claudio Di Leo (AE).

Akanksha Menon, assistant professor in the George W. Woodruff School of Mechanical Engineering, has been awarded $3 million in funding from the Department of Energy (DOE) as part of their Energy Earthshots™ Initiative to advance clean energy technologies within the decade.

The initiative includes a total of $264 million in funding that will support 11 new Energy Earthshot Research Centers (EERCs) led by DOE National Laboratories and 18 university research teams addressing one or more of the specific Energy Earthshots™ that aim to accelerate affordable and reliable clean energy solutions to mitigate the climate crisis to reach a net-zero carbon goal in 2050.

Menon's project, titled Thermo-Chemo-Mechanical Transformations in Thermal Energy Storage Materials and Composites, will bring together Matthew McDowell, associate professor in the Woodruff School, Claudio Di Leo, assistant professor in the Daniel Guggenheim School of Aerospace Engineering, and Jeff Urban from the Lawrence Berkeley National Laboratory, to provide a fundamental understanding of the coupled thermo-chemo-mechanical phenomena in thermal energy storage (TES) materials that will enable low-cost and stable storage.

Chloe Arrington

Martha Grover Named Thomas A. Fanning Chair in Equity Centered Engineering

Jun 04, 2024 — Atlanta, GA

Martha Grover

School of Chemical and Biomolecular Engineering (ChBE) faculty member Martha Grover has been named the College’s Thomas A. Fanning Chair in Equity Centered Engineering. Grover was selected for her efforts to educate engineers who approach their work with an intent to close societal gaps of wealth, power, and privilege by ensuring equitable access to opportunity.

The endowed position was established via the Southern Company Foundation by Southern Company, which has been regularly recognized for its efforts to promote an organizational culture that ensures representation of all groups. Fanning recently retired as chairman, president, and CEO.

Grover is a systems engineer whose work addresses the complexity of molecular organization and how it can solve complicated grand challenges. For instance, she has worked with the Department of Energy for 10 years to create processes for separation and immobilization of millions of gallons of liquid nuclear waste at the Hanford Site in Washington and the Savannah River Site in South Carolina. She’s developed real-time process monitoring of nuclear waste slurries to increase throughput and enhance safety.

Grover’s research also focuses on the origins of life and understanding the essential role of diversity and cooperation. Her other work includes modeling and engineering the self-assembly of atoms and small molecules to create larger scale structures and complex functionality.

Jason Maderer (maderer@gatech.edu)

College of Engineering, Georgia Tech

Georgia Tech Researchers Develop More Efficient Approach for Turning Plant Biomass into Useful Chemicals

Sep 05, 2024 — Atlanta, GA

Illustration of a mechanical impact that creates a reactive environment for depolymerization of biomass into value-added chemicals.

Lignin is one of the most plentiful organic polymers on Earth, making up about 20 to 30 percent of the dry mass of wood and other plants.

Despite this abundance, lignin’s complex structure has challenged researchers in breaking it down into useful components that can be used in the sustainable production of chemicals, plastics, and fuels. Therefore, lignin is often discarded as waste during the production of paper and other plant-based products.

However, researchers at the Georgia Institute of Technology have developed an approach that could transform lignin into valuable chemicals more efficiently than ever before.

The researchers published their findings in the journal ACS Sustainable Chemistry & Engineering on using a method known as mechanocatalysis, which uses physical forces, such as vibration or rotation, in a ball mill to drive chemical reactions without the need for solvents, heat, or high pressure.

Carsten Sievers, a professor in Georgia Tech’s School of Chemical and Biomolecular Engineering (ChBE), explained that the first step in a lignin biorefinery is depolymerization, which breaks lignin down into small molecules.

Professor Carsten Sievers

Brad Dixon, braddixon@gatech.edu